Nueva Alianza Iris Power

3 febrero 2020

3 min de lectura

Preditec ha alcanzado un acuerdo de distribución con la canadiense [...]

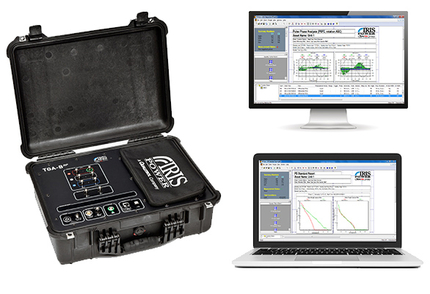

Preditec ha alcanzado un acuerdo de distribución con la canadiense Iris Power, compañía líder en el sector avalada por sus 25 años de experiencia y con un amplio catálogo de sensores e instrumentación para el diagnóstico, entre los que destacan sus soluciones de alta calidad para la monitorización de la condición de parámetros eléctricos en maquinaria rotativa.

Gracias a las soluciones de nuestro nuevo partner tecnológico podemos detectar los fallos en los activos de manera temprana, permitiendo así aumentar su vida útil.

De esta forma, Preditec incorpora a su portfolio de soluciones una tecnología que venían demandando muchos de sus clientes y complementa su oferta de soluciones de monitorización de parámetros mecánicos (como la vibración), consolidando a Preditec como compañía de referencia en el sector predictivo. Fundada en el año 1900, Iris Power es un fabricante canadiense de sensores que se ha convertido en uno de los líderes del mercado gracias a sus soluciones de monitorización de descargas parciales tanto online como offline.

Proporciona equipos y servicios de alta calidad para la recolección de información necesaria para monitorizar efectivamente motores desde 3,3kV, hidrogeneradores y pequeños y grandes turbogeneradores.

Ir a productos Descargas Parciales, AirGap y Flujo Rotórico

En el año 2010 Iris Power creó una alianza empresarial con Qualitrol Corp, corporación estadounidense fundada en el año 1945 y especializada en la monitorización de la condición de activos, que finalmente adquirió a la canadiense.

Servicios

Servicios de ensayos eléctrico online

Los servicios de asesoría/instalación de los sistemas de Iris Power y ensayos eléctricos on-line. Los servicios y pruebas específicas que Iris Power realiza a través de su Grupo de Servicios de campo incluyen:

Determinar la localización de los acopladores capacitivos de Descargas Parciales según tipo de instalación, puesta en marcha del sistema de monitorización en continuo para un óptimo rendimiento del sistema.

- Determinar la localización de la sonda de Flujo.

- Rotórico y puesta en marcha del sistema de monitorización en continuo.

- Determinar la localización y apoyo en la instalación de los sensores de vibración en cabeza de bobinas.

- Determinación de número de sensores y ubicación de sensores para monitorizar el entrehierro de hidrogeneradores.

- Medidas y diagnóstico de Descargas Parciales.

- Medidas y diagnóstico de Flujo Rotórico.

- Medidas y diagnóstico de Vibraciones en Cabeza de Bobinas.

- Ensayo e interpretación de la firma de corrientes estatórica para la detección barras rotas rotores de jaula de ardilla.

- Seminarios y formación en cualquiera de estos temas.

Servicios de ensayos eléctrico offline

Set de ensayos eléctricos off-line para determinar el estado del aislamiento estatórico, rotórico y conductor del bobinado.

- Ensayo de Flujo reducido (ELCID) para detectar imperfecciones en el núcleo magnético.

- Analizador del acuñado mediante ensayo SWA para determinar la eficiencia de los elementos de sujeción de las bobinas en el interior del núcleo magnético.

- Ensayo de Bump Test para determinar la eficiencia de los atados y separadores en cabeza de bobina.

- Ensayo de Sobretensión DC (HIPOT).

- Ensayo de Tangente Delta, Tip-up y Capacidad geométrica.

- Ensayo de Descargas Parciales Off-line.

- Ensayo de Resistencia de Aislamiento, Índice de Polarización e Índice de Absorción.

- Ensayo de Resistencia de bobinado.

- Ensayo EDAII o Polarización/Despolarización.

- Ensayo Surge Test (Ondas de choque) para detectar corto entre espiras.

- Seminarios y formación en cualquiera de estos temas.