Let's build our future - Advanced Factories

3 February 2020

3 min of reading

On March 3, Advanced Factories, an event that will take place in [...]

On March 3, Advanced Factories begins, a three-day event that brings together the most innovative companies in industrial automation, robotics, machine tools and digital manufacturing, along with the technologies that boost industrial competitiveness thanks to new business models, new production processes and the implementation of Industry 4.0.

From our stand C325 you will be able to start building your digital transformation, Grupo Álava's team will be waiting for you to start listening and implementing the first consultative phase: Identify the needs in order to model the solution and intensify the enabling technology.

Would you like a Premium invitation?

Arrange a meeting with us to implement the first consultative phase. Contact marketing@grupoalava.com.

Schedules available:

- Tuesday 3: 16:00, 16:45 or 17:30

- Wednesday 4: 10:00, 10:45, 11:30, 11:30, 12:15, 13:15, 13:00, 13:45, 16:00, 16:45 or 17:30

- Thursday 5: 10:00, 10:45, 11:30, 12:15, 13:00, 13:45

Solutions with digital transformation technologies.

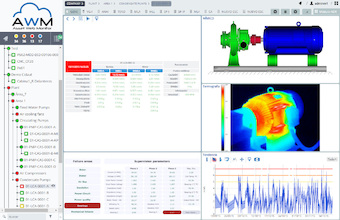

The Industry 4.0 concept implies the use of different technologies to improve current industrial processes. That is why we are the key piece, the technological partner you need to be able to land the different enabling technologies in real projects put into practice. In the solutions area of the Alava Group, we work with agile and design thinking philosophies that allow us to work on ad hoc projects with our clients based on the experience we already have in the different technologies, starting from the specific needs of each manufacturer, designing the necessary pilot phases and proofs of concept and industrializing the solution in a final stage.

Within this technological ecosystem we will show three specific applications based on real projects:

Predictive: Management of the information collected from the plant's critical production assets through wireless sensors and information already existing in plant systems such as PLCs and analysis of this data in an IOT platform.

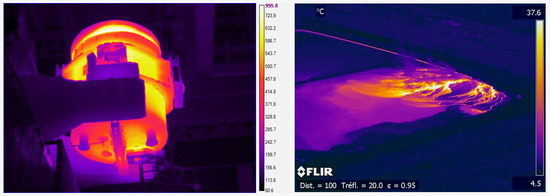

Quality and Safety: Automation of the analysis of images captured with thermographic cameras to identify variations in production processes that affect product quality or environmental safety.

"Thermography allows precise, fast and non-contact temperature measurement of any process. Thanks to it, we will provide our intelligent plant control systems with a sixth sense. Did you know that they can even pick up variations of less than 0.02°C at frequencies of more than 40,000 Hz?"

We will be showing the FLIR A6x5sc | A3x5sc range .

Remote support and training manuals: Virtualization of the information collected in training manuals or plant processes to train employees through virtual and augmented reality and to be able to support them remotely from anywhere in the world in any operational process.

Remote support and training manuals: Virtualization of the information collected in training manuals or plant processes to train employees through virtual and augmented reality and to be able to support them remotely from anywhere in the world in any operational process.