Keys to success in maintenance and reliability planning

May 3, 2011

2 min of reading

The celebration of the Second Spanish Forum was attended by [...]

The Second Spanish Forum was attended by more than 270 maintenance and reliability professionals.

The Second Spanish Forum on Reliability and Predictive Maintenance toured twelve Spanish cities.

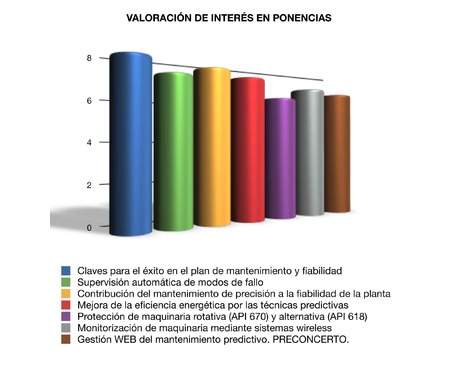

The degree of interest shown by the attendees was presented by means of a survey in which, among other questions, an evaluation of the seven papers presented was requested.

All the presentations were received with a high level of interest by the attendees, although the one with the highest score was "Keys to success in the maintenance and reliability plan" .

To answer the questions raised in the discussions regarding RCM and reliability, Preditec/IRM has planned a course on this effective methodology, aimed at both maintenance and production technicians and engineers to expose and clarify the issues raised in the debate.

Why and how to implement RCM with the objective of properly distributing maintenance tasks between RTF, PM, PdM and PAM

How these tasks, correctly distributed, contribute to an increase in production and utilization of the plant's design capacity as well as a reduction in maintenance costs.

What do the basic concepts used in reliability mean: RER, MTTR, MTBF, Availability, Criticality, OEE... and how can they be used as indicators to justify and measure the financial results achieved with the application of best practices in our work?

To know how to promote and manage an adequate predictive plan, the basis of RCM, and to know the associated techniques.

The course will be given by our reliability area manager, José P. Rayo Peinado, who has more than 30 years of experience in predictive maintenance and its reliability approach.

Historical evolution of maintenance

The four maintenance tactics

- Maintenance on Failure (RTF)

- Preventive Maintenance at fixed intervals (PM)

- Preventive Maintenance according to condition or Predicitive Maintenance (PdM)

- Proactive Maintenance

RCM History

Some basic conceptsReliability, RER, OPRER, MTTR, MTTF, MTBF, Availability, Criticality, OEE

Why and how to implement RCM Why implement RCM: System grouping, Boundary definition, Asset listing, Criticality, Functions, Functional failures, Failure modes, FMEA, FMECA

Distribution of maintenance tasksRTF, PM, PdM, PdM Techniques, Vibration, Thermography, Oil Analysis, Ultrasonic Pickup, MCA, PAM

How to manage RCM

Process indicators (KPI's)

- Dates: June 29 and 30, 2011.

- Location: Madrid